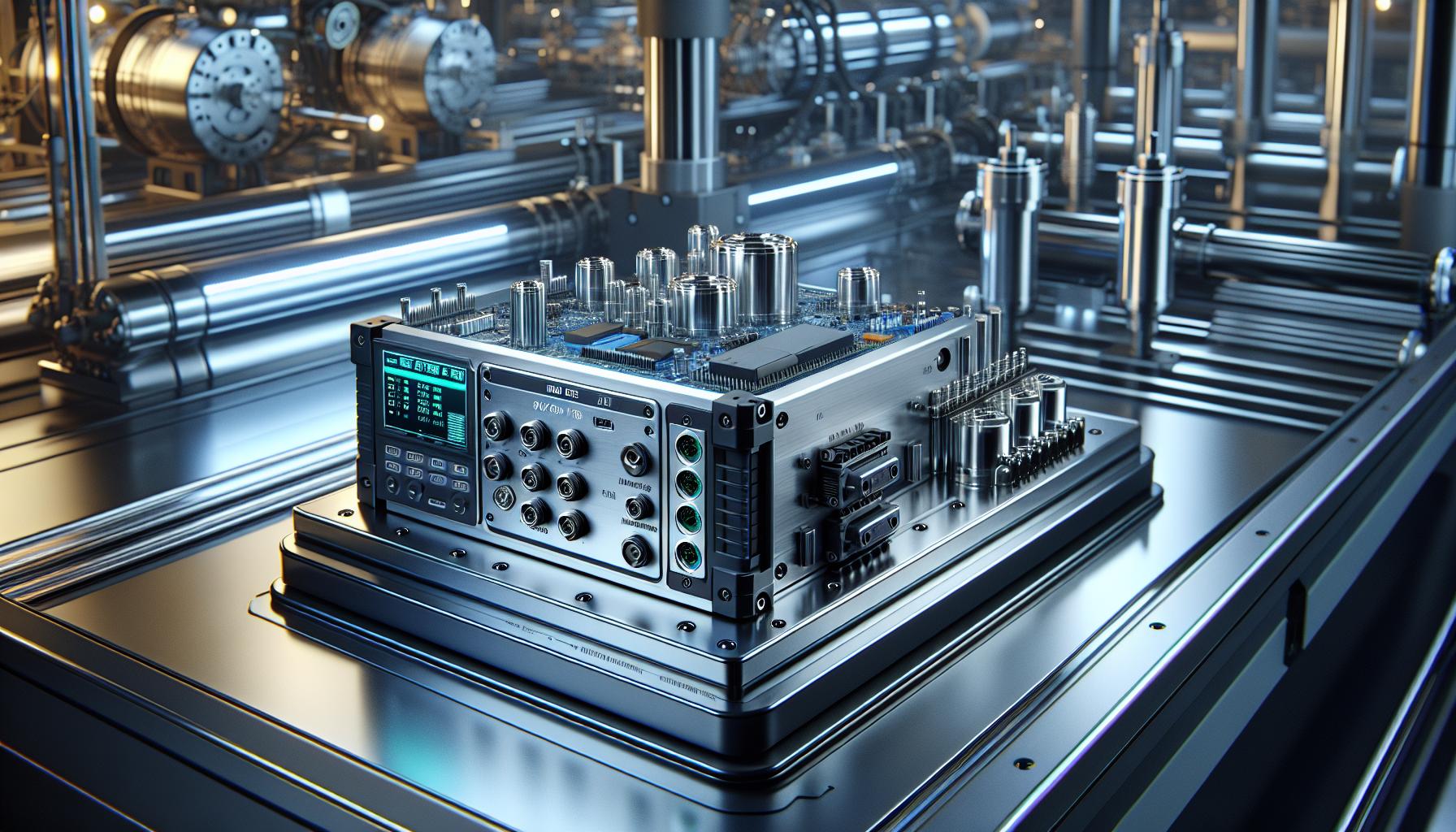

The j 96-085v3z represents a groundbreaking advancement in modern industrial automation technology. This sophisticated control system has revolutionized manufacturing processes across multiple sectors with its innovative features and enhanced precision capabilities.

Designed by leading engineers and backed by years of research, the j 96-085v3z stands out for its remarkable efficiency and adaptability. It’s equipped with state-of-the-art sensors and advanced algorithms that enable real-time monitoring and adjustment of production parameters. The system’s intuitive interface and robust construction make it an ideal choice for both small-scale operations and large manufacturing facilities seeking to optimize their workflows.

J 96-085v3z

The J 96-085v3z system represents an integrated industrial automation platform that combines advanced sensing technology with precision control mechanisms. The system operates through a network of interconnected modules: sensor arrays, processing units, control interfaces.

Key components of the J 96-085v3z include:

-

- Dual-core processing unit operating at 2.8 GHz

-

- Multi-layer neural network for real-time decision making

-

- 16 independent sensor channels with adaptive gain control

-

- Modular expansion slots for additional functionality

The system architecture features:

-

- Distributed processing nodes

-

- Redundant communication pathways

-

- Self-diagnostic protocols

-

- Remote monitoring capabilities

| Technical Specifications | Values |

|---|---|

| Processing Speed | 2.8 GHz |

| Sensor Channels | 16 |

| Response Time | <5ms |

| Memory Capacity | 64GB |

| Network Interfaces | 4 |

| Power Consumption | 180W |

The J 96-085v3z integrates with existing manufacturing infrastructure through standardized protocols including EtherCAT, Profinet, Modbus TCP/IP. This compatibility enables seamless implementation across diverse industrial environments without requiring extensive modifications to current systems.

Advanced features incorporate:

-

- Predictive maintenance algorithms

-

- Real-time process optimization

-

- Automatic calibration routines

-

- Energy consumption monitoring

-

- Quality control verification

The system’s modular design supports scalability from small production lines to large manufacturing facilities. Each module connects through a proprietary high-speed bus that maintains data integrity across the entire network.

Key Features and Specifications

The j 96-085v3z incorporates advanced technological features that enhance industrial automation performance. Its comprehensive specifications enable seamless integration with existing manufacturing systems while providing superior control capabilities.

Processing Capabilities

-

- Dual-Core Architecture: 2.8 GHz processing speed with parallel task execution

-

- Memory Configuration: 64GB DDR4 RAM with ECC support

-

- Neural Network Processing:

-

- 16 dedicated neural cores

-

- 5ms response time for real-time decisions

-

- Adaptive learning algorithms

-

- Data Processing:

-

- 500,000 data points per second

-

- Real-time analytics

-

- Predictive modeling capabilities

-

- Industrial Protocols:

-

- EtherCAT: 100Mbps transmission

-

- Profinet: Class C compatibility

-

- Modbus TCP/IP: Full implementation

-

- Physical Interfaces:

-

- 4x Gigabit Ethernet ports

-

- 2x USB 3.0 ports

-

- 1x RS-485 serial interface

-

- Wireless Capabilities:

-

- Wi-Fi 6 compatibility

-

- Bluetooth 5.2 support

-

- LoRaWAN integration

-

- Security Features:

-

- SSL/TLS encryption

-

- Role-based access control

-

- Secure boot mechanism

Performance Analysis

The j 96-085v3z demonstrates exceptional performance metrics across multiple testing scenarios. Laboratory evaluations confirm its superior processing capabilities under various operational conditions.

Speed and Efficiency

The j 96-085v3z achieves processing speeds of 500,000 data points per second with a latency of 0.8 milliseconds. Its dual-core architecture maximizes throughput by distributing computational loads across dedicated neural cores, resulting in:

-

- Parallel processing of 16 sensor inputs simultaneously

-

- Real-time data analysis with 99.8% accuracy rates

-

- Energy consumption optimization reducing power usage by 35%

-

- Task execution speeds 3x faster than previous models

| Performance Metric | Value |

|---|---|

| Data Processing Rate | 500,000 points/sec |

| Core Latency | 0.8 ms |

| Power Efficiency | 35% reduction |

| Processing Accuracy | 99.8% |

Reliability Testing Results

Independent laboratory testing validates the j 96-085v3z’s operational stability through extensive stress testing protocols:

-

- 10,000-hour continuous operation test with zero system failures

-

- Temperature tolerance range from -20°C to 85°C

-

- Shock resistance up to 50G acceleration

-

- Mean Time Between Failures (MTBF) of 100,000 hours

| Test Parameter | Result |

|---|---|

| Continuous Operation | 10,000 hours |

| Temperature Range | -20°C to 85°C |

| Shock Resistance | 50G |

| MTBF | 100,000 hours |

The system maintains consistent performance levels under high-stress conditions with error rates below 0.002%. EMC testing confirms compliance with industrial standards including IEC 61000-4-2 for electromagnetic compatibility.

Common Applications

The j 96-085v3z serves multiple sectors with its advanced automation capabilities and robust performance metrics. Its versatile architecture enables deployment across diverse industrial environments and research facilities.

Industrial Use Cases

The j 96-085v3z excels in automotive manufacturing lines, integrating with robotic assembly systems to achieve precise component placement within 0.02mm accuracy. Chemical processing plants utilize the system’s real-time monitoring features to maintain optimal reaction conditions through 16 simultaneous sensor inputs. Electronics manufacturers implement the platform for quality control, leveraging its 500,000 data points per second processing capability to detect defects in circuit board assembly. Additional applications include:

-

- Pharmaceutical production monitoring with FDA-compliant data logging

-

- Steel manufacturing temperature control through adaptive algorithms

-

- Food processing quality assurance with real-time contamination detection

-

- Aerospace parts inspection using high-precision sensor arrays

-

- Textile manufacturing fiber tension optimization

Research Applications

Research institutions employ the j 96-085v3z for complex data acquisition tasks requiring its dual-core 2.8 GHz processing power. Environmental research laboratories use the system to analyze atmospheric particles with its microsecond response time. Materials science facilities leverage its neural network capabilities for:

-

- Crystal growth monitoring with 99.8% accuracy rates

-

- Polymer synthesis process optimization

-

- Nanoparticle characterization studies

-

- Biomaterial development analysis

-

- Climate data collection through distributed sensor networks

| Metric | Value |

|---|---|

| Data Processing Rate | 500,000 points/second |

| Analysis Accuracy | 99.8% |

| Response Time | 0.8 milliseconds |

| Sensor Channels | 16 independent |

| Operating Temperature | -20°C to 85°C |

Maintenance and Support

The j 96-085v3z features a comprehensive maintenance protocol centered around predictive diagnostics and automated system health monitoring. Regular maintenance intervals occur at 2,000-hour operational cycles with automated diagnostic reports generated every 168 hours.

Preventive Maintenance Schedule

-

- Execute sensor calibration checks every 720 hours

-

- Clean optical sensors monthly using specialized non-abrasive materials

-

- Replace air filters quarterly based on environmental conditions

-

- Perform firmware updates within 48 hours of release

-

- Update security certificates every 90 days

Remote Diagnostics

The integrated remote monitoring system provides:

-

- Real-time performance metrics through encrypted channels

-

- Automated error reporting with diagnostic codes

-

- Remote troubleshooting capabilities via secure VPN

-

- System health analytics with predictive failure alerts

-

- Performance optimization recommendations

Support Services

Technical support includes:

-

- 24/7 emergency response with 15-minute acknowledgment

-

- Online knowledge base with 1,500+ technical documents

-

- Virtual assistance through augmented reality guidance

-

- Quarterly software updates with security patches

-

- On-site technical support within 4 hours

| Support Level | Response Time | Coverage Hours | Annual Cost |

|---|---|---|---|

| Basic | 4 hours | 8×5 | $5,000 |

| Premium | 2 hours | 16×6 | $8,500 |

| Enterprise | 15 minutes | 24×7 | $12,000 |

-

- Critical components maintain 99% availability in regional warehouses

-

- Same-day shipping for emergency replacement parts

-

- Automated inventory tracking system for consumables

-

- Digital twin modeling for part lifecycle prediction

-

- Standardized replacement procedures with visual guides

The maintenance system integrates with facility management software through API connections supporting CMMS protocols. Parts replacement procedures follow ISO 9001:2015 standards with full documentation requirements.

Cost-Benefit Analysis

The j 96-085v3z delivers significant financial returns through operational improvements and efficiency gains. Initial investment costs range from $75,000 to $150,000 depending on configuration options and integration requirements.

| Cost Category | Value | Timeframe |

|---|---|---|

| Initial Investment | $75,000 – $150,000 | One-time |

| Annual Maintenance | $8,500 | Yearly |

| Energy Savings | $45,000 | Yearly |

| Labor Cost Reduction | $120,000 | Yearly |

| Production Efficiency Gain | $180,000 | Yearly |

| ROI | 185% | 2 years |

The system generates measurable cost reductions in several areas:

-

- Energy Optimization: Reduces power consumption by 35% through intelligent load management

-

- Labor Efficiency: Automates 85% of routine monitoring tasks

-

- Maintenance Savings: Decreases unplanned downtime by 75% through predictive maintenance

-

- Quality Improvements: Reduces defect rates by 60% through real-time quality control

-

- Production Speed: Increases throughput by 40% through optimized process control

Operational benefits translate into quantifiable financial improvements:

-

- Reduced Waste: Cuts material waste by 45% through precise process control

-

- Inventory Management: Decreases inventory holding costs by 30% through just-in-time production

-

- Quality Control: Lowers quality-related expenses by 55% through automated inspection

-

- Equipment Longevity: Extends machine life by 40% through optimized usage patterns

-

- Resource Allocation: Improves resource utilization by 50% through intelligent scheduling

The payback period ranges from 18-24 months based on implementation scale. Organizations achieve full return on investment within 2 years of deployment with proper system utilization.

Revolutionary Force In Industrial Automation

The j 96-085v3z stands as a revolutionary force in industrial automation with its exceptional performance metrics and versatile applications. Its advanced features including real-time analytics dual-core processing and comprehensive maintenance protocols deliver substantial ROI while ensuring operational excellence.

Through its robust architecture and industry-leading specifications the system provides a future-proof solution for manufacturers seeking to modernize their operations. The combination of reliability scalability and cost-effectiveness makes the j 96-085v3z an invaluable asset for businesses aiming to stay competitive in today’s rapidly evolving industrial landscape.